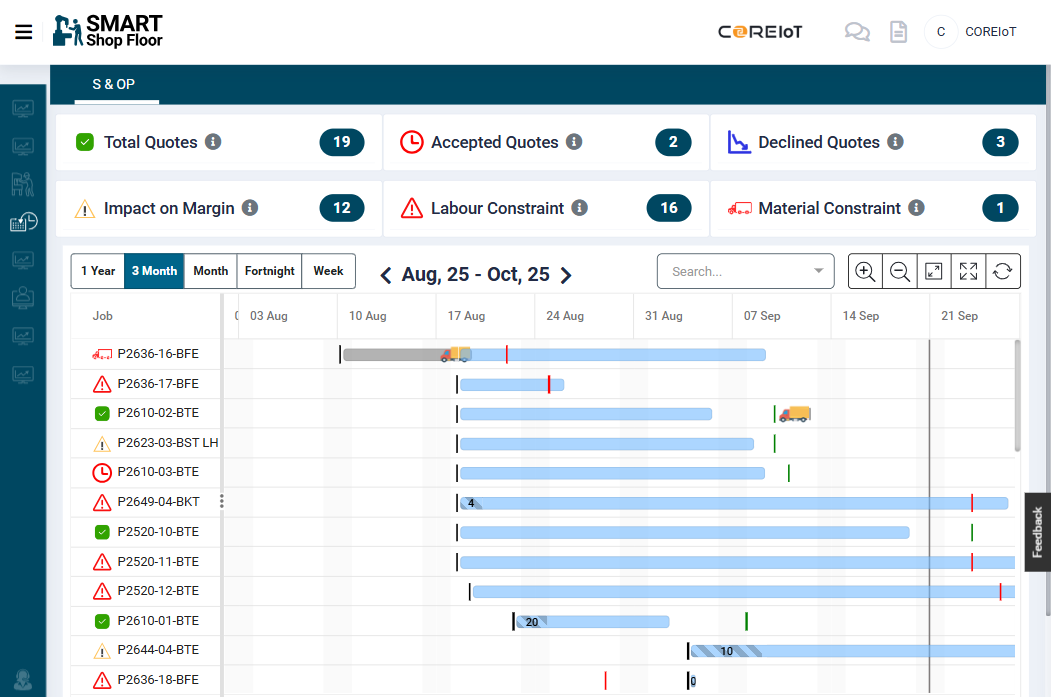

Sales and Operational Planning

Stop Reacting to Demand - Plan For It

Set yourself up for success by determining now what steps you need to take in the year ahead.

Match future demand with machines, manpower and material to plan a way forward with the most profit, instead of scrambling to keep up with whatever work comes through the door.

Benefits

Stop Playing Catch-Up

Get a shop floor solution that puts you one step ahead.

Strategic Growth Planning

Identify required resources well in advance to capture the most business possible, turning reactive decision-making into proactive strategic planning

Seamless Operational Flow

Digitally connect all departments with automated handoffs and real-time visibility, ensuring work flows smoothly without bottlenecks or things falling through the cracks

Accurate Cost Control & Profitability

Know your true costs through closed-loop costing from shop floor to ERP, eliminating guesswork and protecting margins on every job

Confidence for Sales and Customer Service Teams

Ability to accurately forecast lead times for new work is critical. Ensuring that your promises are something that you can deliver in full and without overtime.

Sales and Operational Planning

Plan your capacity to grow your business to the fullest

Allow your team to accurately forecast committed dates for new work and plan beyond your current workload. An operational calendar strategically fills your schedule by combining confirmed business with quoted work, revealing your precise remaining capacity for new jobs. Use this forecast to plan for the people, machines and inventory you'll need.

-

Extends your planning horizon to spot opportunities earlier

-

Helps you prioritise quotes by focusing on the most profitable jobs you're confident in winning

-

Compare overtime, subcontracting, hiring, or equipment investment options with real numbers, not guesswork

Estimating and Quoting

Bid smarter with real

capacity data

Stop losing money on jobs or losing jobs to competitors because you're guessing at costs, resources and delivery dates. Our capacity-based quoting tool uses real operational data to help you bid with confidence. Capacity constraint alerts identify labour, equipment and material shortages, allowing you to compare scenarios to determine the best margin and price to offer.

-

Shows when your team is fully booked with cost analysis for the most profitable approach

-

Self-learning algorithm improves promise date accuracy with every completed job

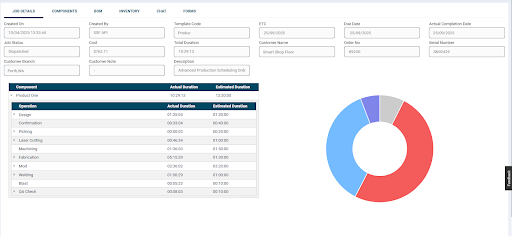

Costing

Unlock profitability with closed-loop costing from shop floor to ERP

Without easy shop floor data capture, accurate costing is impossible, leaving you to rely on gut feeling. Smart Shop Floor captures actual material usage, precise labour hours, and machine work time, then seamlessly syncs this data with your ERP for cost accuracy that was previously impossible. This way you get a complete cost breakdown, including rework, to maintain margins.

-

Log exact labour costs per job, not estimates

-

Compare quoted vs. historical labour trends to optimise pricing and identify profit leaks

-

Track additional material usage to pinpoint waste

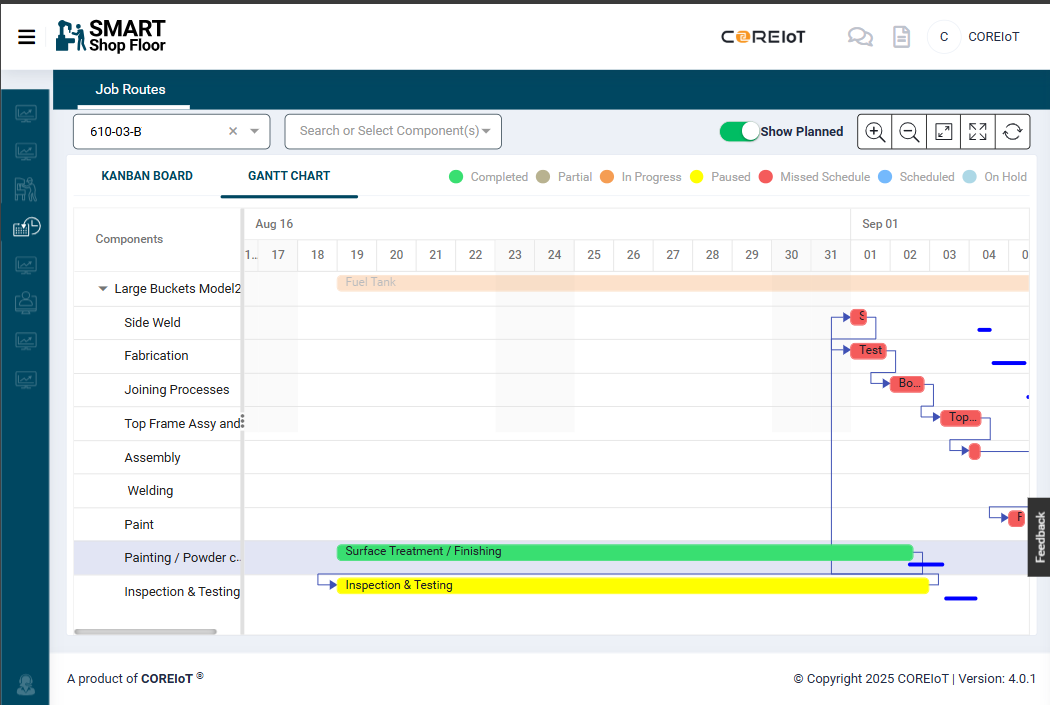

Automated Department Handoffs

Tell every department

when it’s go time

Smart Shop Floor ensures every job follows a standardized path through your manufacturing workflow. It digitally links all key departments – from purchasing and engineering to picking, machine operations, and dispatch – ensuring seamless coordination. When an order is ready for the next stage, it's automatically added to that department's workload.

-

Individual and department dashboards with prioritised tasks and deadlines

-

Automatic handoffs ensure no work falls through the cracks between teams

-

Real-time job status eliminates chasing updates and confusion

The shop floor scheduling solution that gets the job done.

We bring together everything you need to schedule and manage your shop floor. Save time, reduce downtime, and boost productivity.