Scheduling that evolves

with your production

reality

A Manufacturing Execution System with automated

scheduling and work allocation that bridges your

people and operations in real time, custom-made

for job shops and made-to-order manufacturers.

Old Vs New

Grow From Generic to Purpose-Built Scheduling

A one-size-fits-all approach just doesn't work for job shops and make-to-order manufacturers

Battling pen-and-paper scheduling Or ERP bolt-on modules that operate in hypotheticals?

-

Lack of visibility

-

Clients chasing update

-

Constantly changing priorities

-

Racked up overtime

-

High inventory

-

Expensive rework

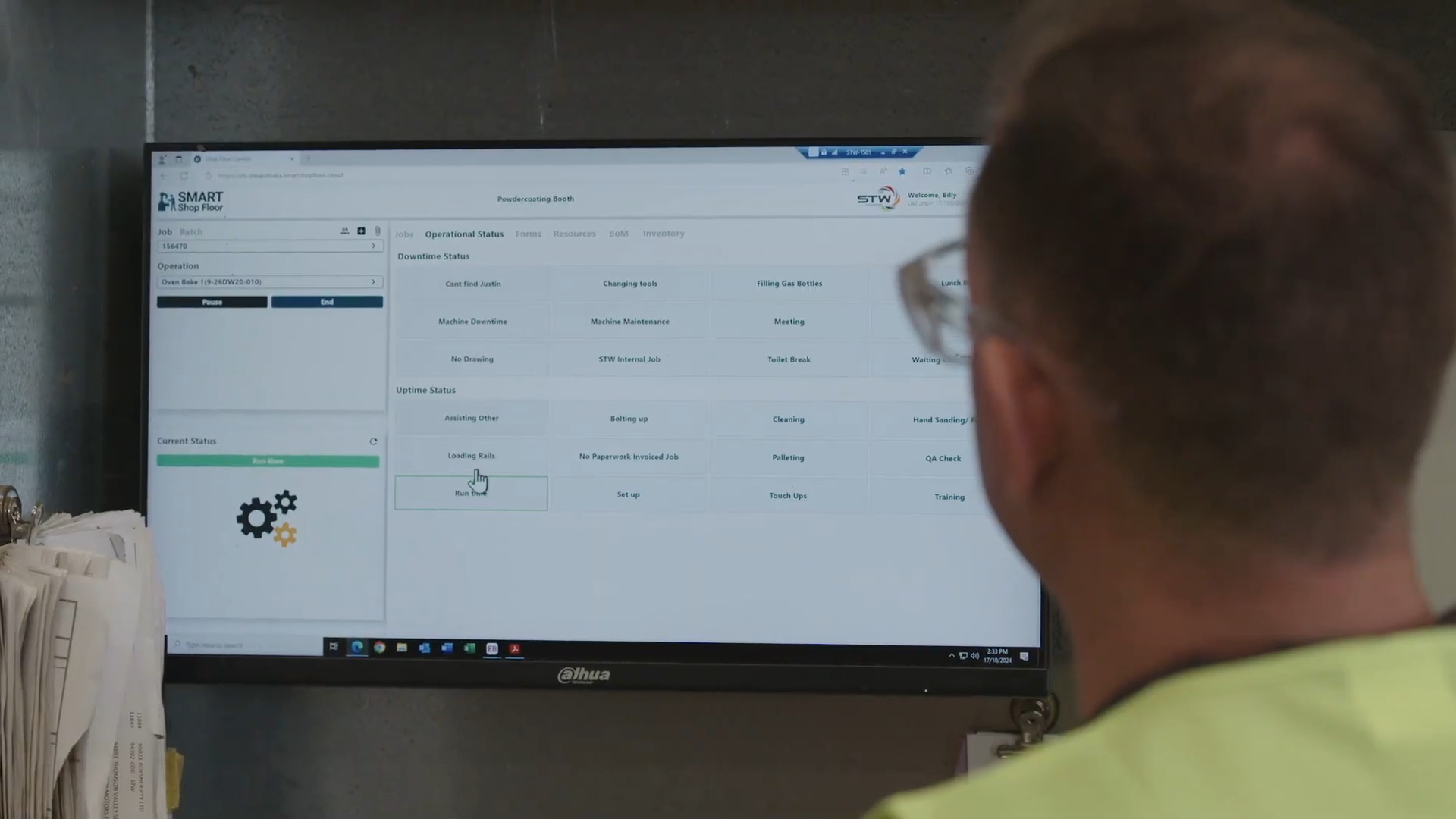

Automated scheduling and work allocation is your digital production scheduler - planning, assigning and rescheduling work in real-time

-

Improved capacity

-

Higher customer satisfaction

-

Faster lead times

-

On-time delivery

-

Reduced overtime

-

Lower inventory

Modules

Drive Profitability with Streamlined Operations

Complete shop floor control with sales planning, scheduling, and real-time production visibility all in one system

Sales and Operational Planning

Use real data to power your strategic planning, from quotations with accurate costs and delivery dates to making informed decisions about hiring, equipment investment, or subcontracting. An 18-month operational calendar lays out your future production plan in clear detail.

Automated Production Scheduling

Fully automate your production planning, scheduling and work allocation. As work progresses, the schedule updates in real-time, keeping everything on track even when the unexpected happens. An optimised schedule and clear work allocation unlocks capacity and accelerates lead times.

Inventory Management

Smart Shop Floor's inventory management connects your ERP directly with the shop floor, providing digital BOM and pick lists for operators that reduce manual stocktaking and save hours every week. AI material management compares real-time stock levels with incoming orders and flags material shortages before they become production delays.

Digital Forms

Operators complete and file safety, quality, and maintenance forms on their tablets, eliminating the hassle of manual paperwork. Digital forms are quicker to complete and automatically saved so you can find what you need.

Customer Portal

Differentiates your business against the competition by providing a dedicated, digital collaboration portal that gives customers direct line of sight from order placement to dispatch. Your portal becomes a collaborative hub where customers can track work orders in real-time and communicate directly with your team, answering the constant "How's my order going?" inquiries.

Rotable Management

High-value components cycle through inspection, repair, and back into service—but most operations manage this in spreadsheets with no connection to production scheduling. Smart Shop Floor's Rotable Management integrates the entire lifecycle so you control approvals, costs, inventory and turnaround times from one system.

Included Features

Core Features

Add-On Modules

Connected Visibility At Every Stage

Go Live

Get Started In 6 to 8 Weeks

Our setup isn't about software – it's about getting your people comfortable and productive

-

Implementation Specialists work with your team to document and optimize your production workflow

-

Workshops are conducted to understand your business and set up Smart Shop Floor to match your unique workshop configuration

-

Connect seamlessly with your existing ERP and other systems

-

Hands-on sessions get your team comfortable with our straightforward tools

-

We establish daily routines that make the system part of your standard workflow

-

Start with key departments to build confidence before full deployment

-

Your system activates with our team right there to back you up

-

We gradually add advanced features as your team masters the basics

-

Continuous improvement processes keep refining your system’s performance

-

Regular check-ins ensure you’re getting maximum value from your investment

The shop floor scheduling solution that gets the job done.

We bring together everything you need to schedule and manage your shop floor. Save time, reduce downtime, and boost productivity.