Advisory

Gap Analysis & Strategic Advisory

Get clear directions for your manufacturing future

Stop guessing at solutions. Get expert guidance tailored to your specific needs.

The Shop Floor Void

You've invested in business software – whether ERP, MRP or something similar. But your factory floor is still operating like it's 1970. There's promising tech everywhere and everyone's raving about this or that. You know there's potential to improve, but you're stuck wondering:

-

What improvements are actually possible for your operation?

-

Which software systems will solve your real problems?

-

How do you choose the right tools without getting burned?

-

How do you connect everything and get it working properly?

-

Who can you trust to point you in the right direction?

Manufacturing Gap Analysis for Australian Job Shops

Smart Shop Floor offers independent consulting to help you sort through these questions because every shop is different and we want to find the right solutions for your specific operation. We're not here to push our own products. The same process we use to get factories ready for new scheduling software – connecting existing systems, rolling out digital lean tools, and mapping out manufacturing processes step-by-step – is exactly what reveals the real gaps in your operation.

What you get

-

Onsite visit from our implementation team

-

Complete review of challenges, goals, and step-by-step breakdown of your manufacturing process

-

Detailed report recommending the best systems to address identified operational gaps

-

Clear roadmap for implementation priorities

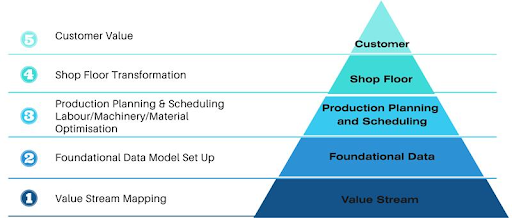

Success Framework

Step 1

Value Stream Mapping

This Lean manufacturing technique visually maps out your flow of materials, information and manufacturing operations needed to make your product from start to finish. Breaking down your current process reveals waste and improvement opportunities, leading to reduced lead times and costs, plus improved quality. Using these findings, we design a new workflow map outlining the streamlined process your operation should follow.

Step 2

Foundational Data Model Set Up

Manufacturing technology runs on good data. We figure out what information your systems will need and the best way to capture and organize it to achieve your primary objectives.

Step 3

Production Planning & Scheduling

If just-in-time scheduling or production planning emerges as a priority, we implement it here. This acts as a project management tool with immediate impact on streamlining inventory and job flow. We also investigate ways to optimise your workforce, equipment and materials.

Step 4

Shop Floor Transformation

We review your current setup and recommend a change management strategy for introducing operator technology gradually, including training approaches and a rollout plan that ensures team comfort with new systems.

Step 5

Customer Value

Data can also be mission-critical for your customers and sharing it can give you a competitive edge. But how do you balance risk with reward? Transparency could mean providing access to order status updates, lead times, or compliance data like carbon emissions. We'll help you determine what provides the most value for your clients and how to do it securely.

The shop floor scheduling solution that gets the job done.

We bring together everything you need to schedule and manage your shop floor. Save time, reduce downtime, and boost productivity.