Shop Floor Management

Essential Operator Tools For Improved Efficiency

Support Better Work, Every Shift

Our operator app is designed for the reality of a busy shop floor with a distraction-free and dead-simple user interface. It delivers everything your production team needs at their fingertips: job information, communication tools, and digital forms. Built to be foolproof, while keeping your team productive and informed.

Benefits

Give Your Team the Right Tools

Everything your production team needs to stay productive and informed.

Clarity and Direction in Work Assignments

Automated scheduling gets the plan out to your people so they can jump on it. They get a balanced, realistic workload for the day that gives them clarity on priorities and pace.

Real-time Connection Between Shop Floor and Back Office

No more information black holes between office and shop floor. Digitising information flow and processes means that critical information now flows automatically between your two business halves.

Turn Wasted Minutes Into Productive Hours

The full suite of tools makes operators more efficient, saving 45-60 minutes per operator, per shift. We create these savings by reducing the time burden of manual paperwork, one-way communication and unproductive downtime.

Catch Issues Early, Fix Them Fast

Problems get spotted earlier and solved quicker. When something's not right, the right people know about it immediately and can jump in before small issues become big delays. Less waiting around, less rework, more time actually making things.

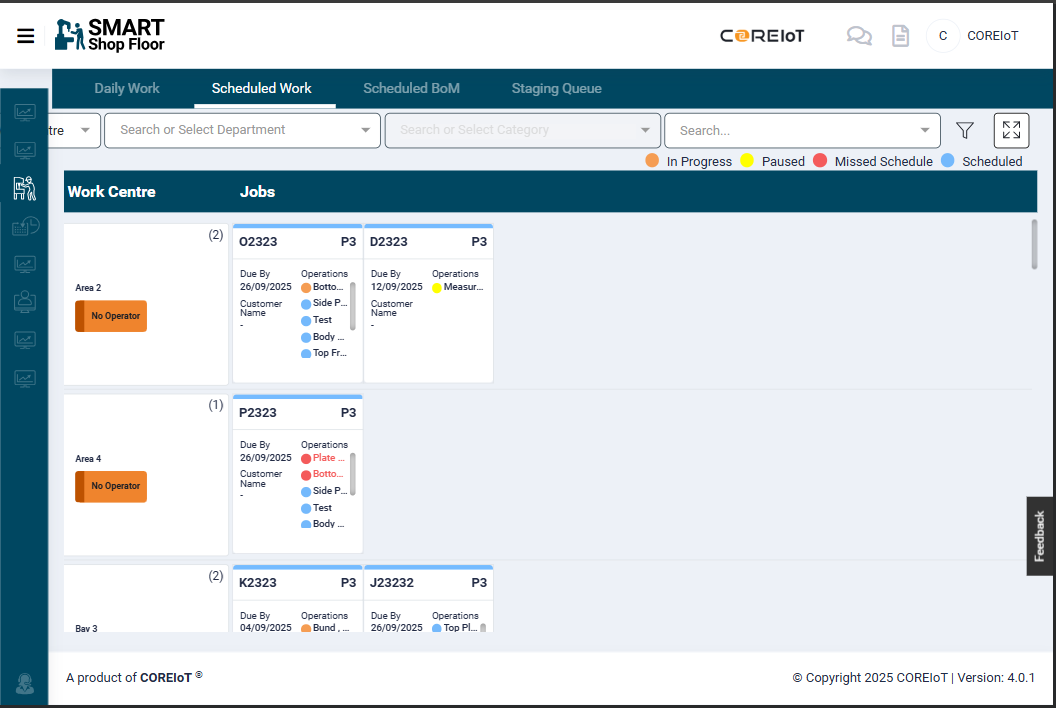

Production Boards

Digital Daily Work Boards So Everyone's In the Know

Gantt or Kanban-style production boards display your live production schedule, updated in real time with everyone's ongoing tasks. At a glance, both supervisors and factory operators get a complete view of the day's plan, along with the status of every job

-

One-tap job updates from the shop floor instantly notify the whole team

-

Priority highlighting so VIP customer work never gets buried

-

Cross-device access - same live information whether you're at a desk or walking the floor

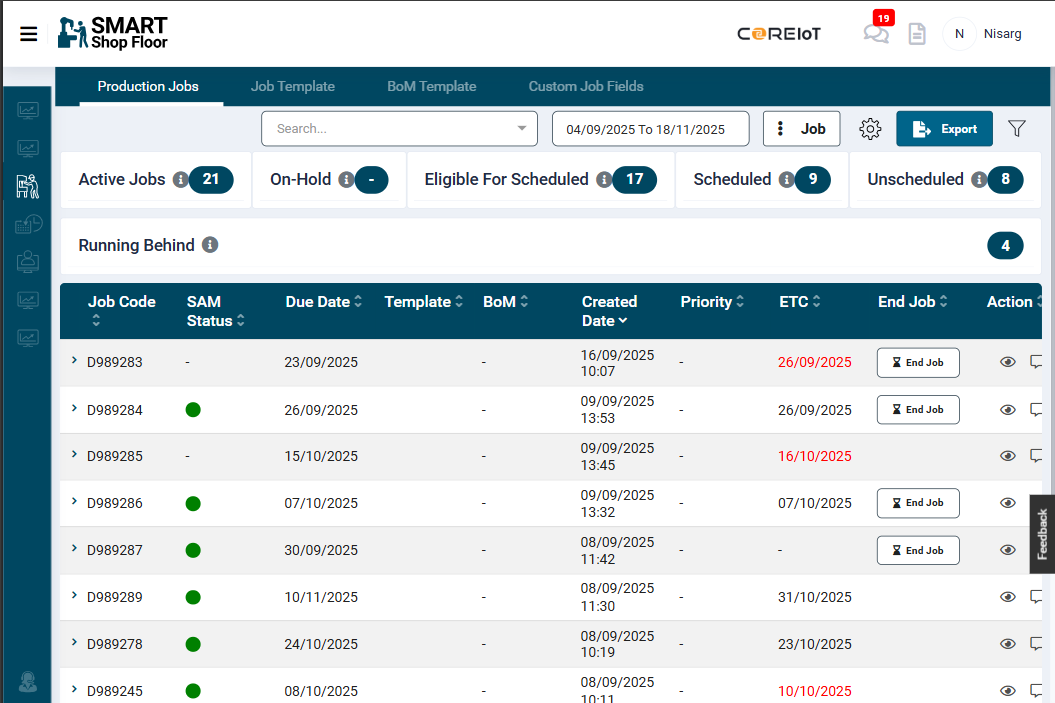

Digital Job Cards

Complete Job Packages,

In One Place

No more chasing down drawings or wondering what materials you need. Each work order comes with everything required to do it properly, all linked within the operator app - drawings, instructions, material lists, and digital forms. Now everything is easily referenceable and stays with the job from start to finish.

-

Automatic time tracking captures exact labour costs for every job

-

Job-specific material lists with one-tap inventory tracking of what's actually used

-

Built-in quality and procedural checklists ensure nothing gets missed or skipped

Shop Floor Communication

Direct Communication to Improve Collaboration and Minimise Setbacks

Operators communicate directly with supervisors or the back office from their workstation, speeding up response time when asking questions or requesting assistance. Streamlined communication reduces unnecessary movement around the shop floor, improving both efficiency and safety.

-

Text and photo messaging quickly clarifies any machine or quality issues

-

Capture comments or updated work instructions instantly

-

Andon light integration makes it immediately visible when assistance is needed

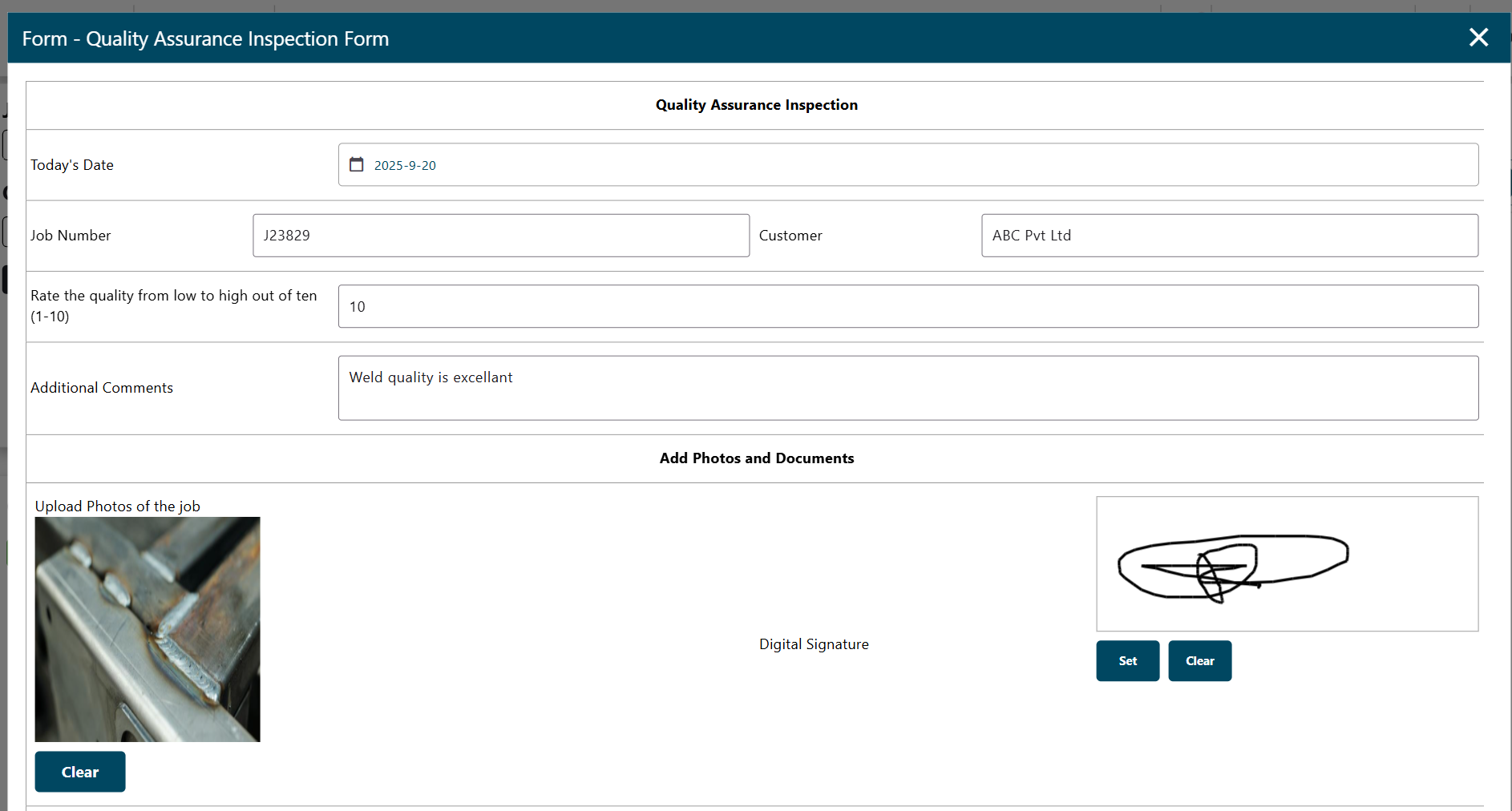

Digital forms

Paperwork That Actually Gets Done

Complete quality, safety and maintenance forms right on your tablet - no more hunting for clipboards or figuring out which form to use. Everything's built into your workflow, so you can tick off requirements quickly and get back to work.

-

Pre-built forms for every task - no guessing what information is needed

-

Faster completion with photos, signatures, and automatic timestamps

-

Mandatory safety and quality checkpoints guide you through the right process every time

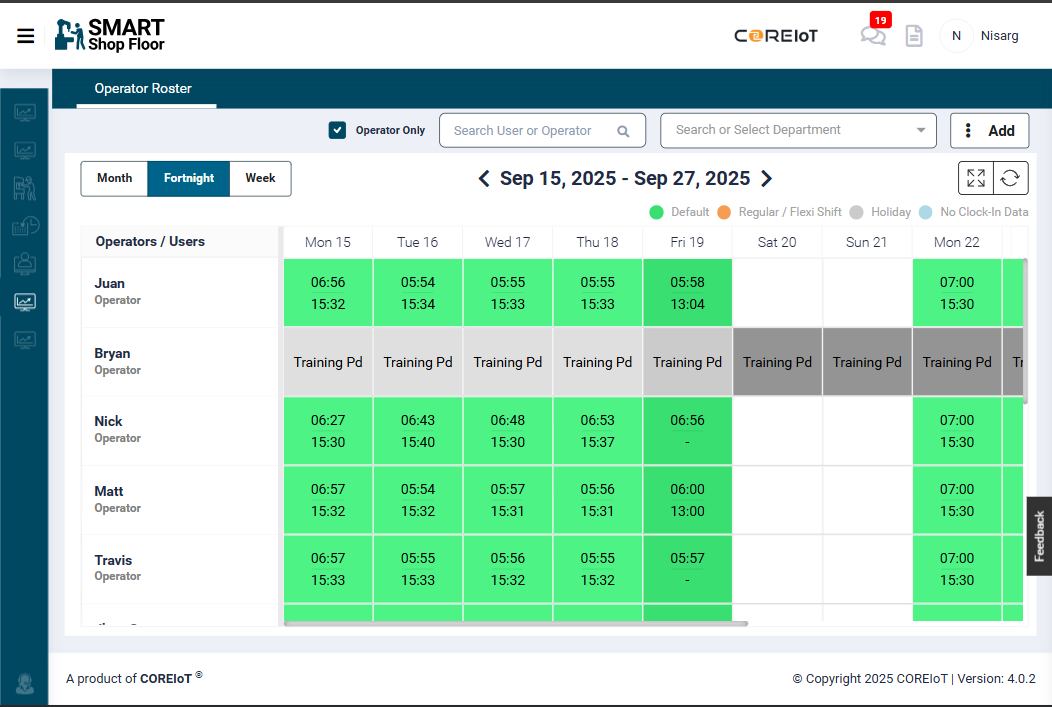

Workforce Management

Integrated Workforce Management Gets Important Information Right Every Time

Integrated workforce management features handle work assignments, staff rosters, timesheets and attendance. Accurate data is captured directly from the shop floor, eliminating error-prone manual data entry. Detailed time tracking for every operation gets sent back to your ERP, providing accurate job costing.

-

Self-managing work assignments adapt to changing conditions so operators stay productive, while supervisors focus on bigger priorities instead of daily task juggling

-

Adaptive rescheduling adjusts to current conditions and balances work assignments - operators simply move to their next assigned task

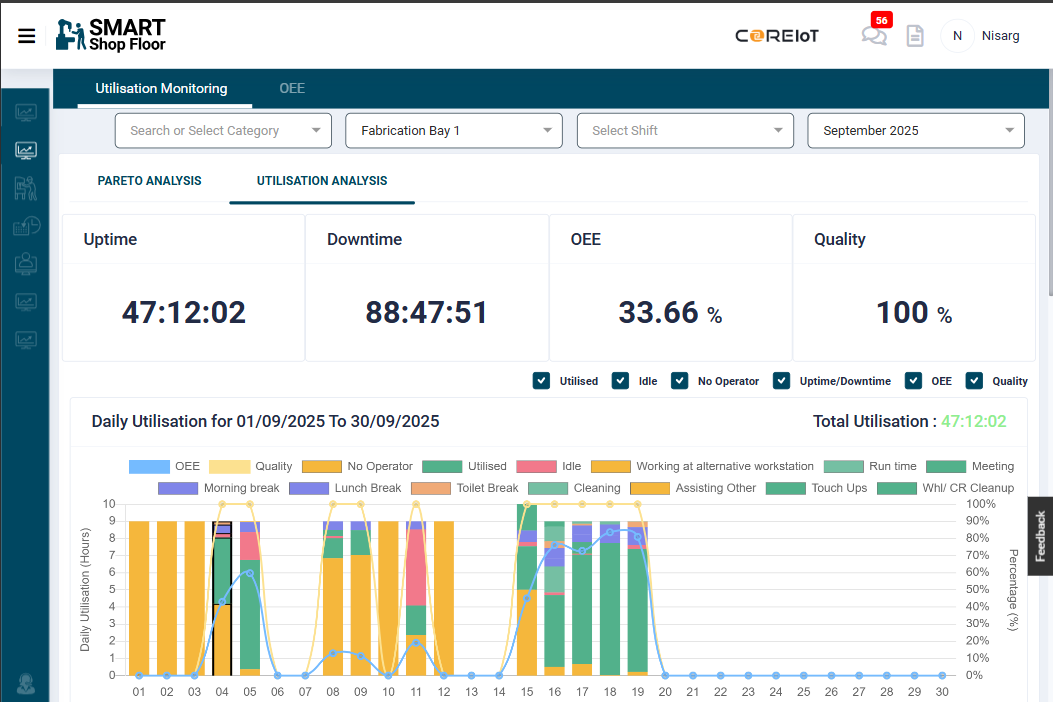

Downtime Alerting

Get Ahead of Problems With Downtime Alerts

Smart Shop Floor keeps your team ahead of downtime situations so they stay productive. Operators record downtime reasons with one-touch event logging to identify bottlenecks and track productivity.

-

Andon light integration changes colour based on operator actions, giving supervisors instant visual alerts for downtime and assistance requests

-

Automatic supervisor notifications when machines or operators sit idle beyond normal timeframes

The shop floor scheduling solution that gets the job done.

We bring together everything you need to schedule and manage your shop floor. Save time, reduce downtime, and boost productivity.