Rotable Management

Complete lifecycle control for high-value serviceable parts

Manage rotables from mine to shop floor and back into service.

Ideal for OEMs, asset managers, or mining operations with in-house maintenance. For the first time, rotable asset management integrates directly with production scheduling and customer communication—eliminating the delays and disconnects that tie up capital and extend downtime.

What is a repairable spare?

In the mining industry, rotable parts are high-value components that can be repaired or refurbished and reused multiple times. They "rotate" through a cycle of being in service, removed for repair, and then returned to inventory for future use.

How Replaceable Spares Work in Smart Shop Floor

Benefits

Get More Value from Every Rotable

Go full throttle with with proper capital tracking, availability planning, and cost analysis.

Features

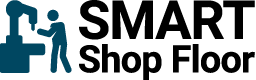

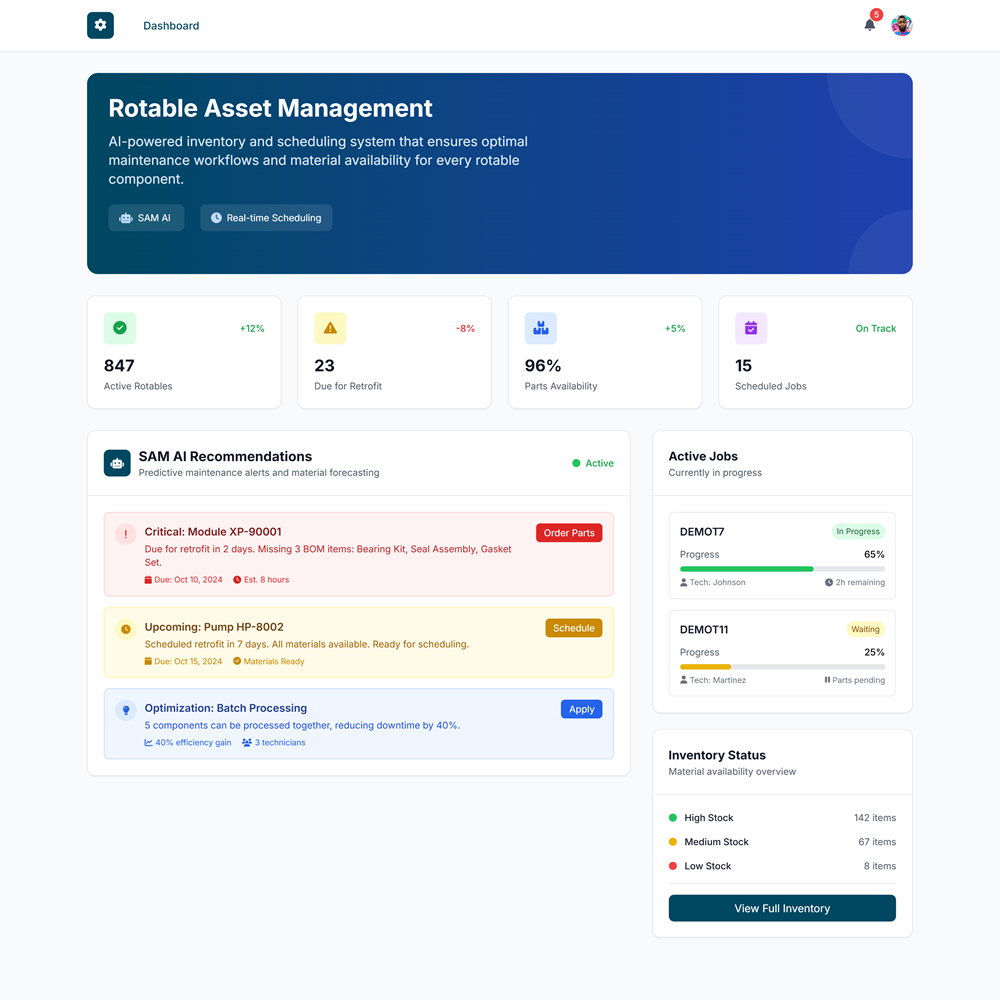

Rotables on the Fixed Assets Dashboard

Rotating spares are fixed assets with a unique ID to track them as they come in and out of service. To initiate servicing in a timely manner and stay on top of strict requirements, each item has a customised maintenance plan with usage-based or scheduled reminders. The Rotables Dashboard gives you access to everything you need to manage serviceable assets the same way you track work orders in Smart Shop Floor. You can see active jobs and complete jobs, saved inspection forms, service history, and cost trends.

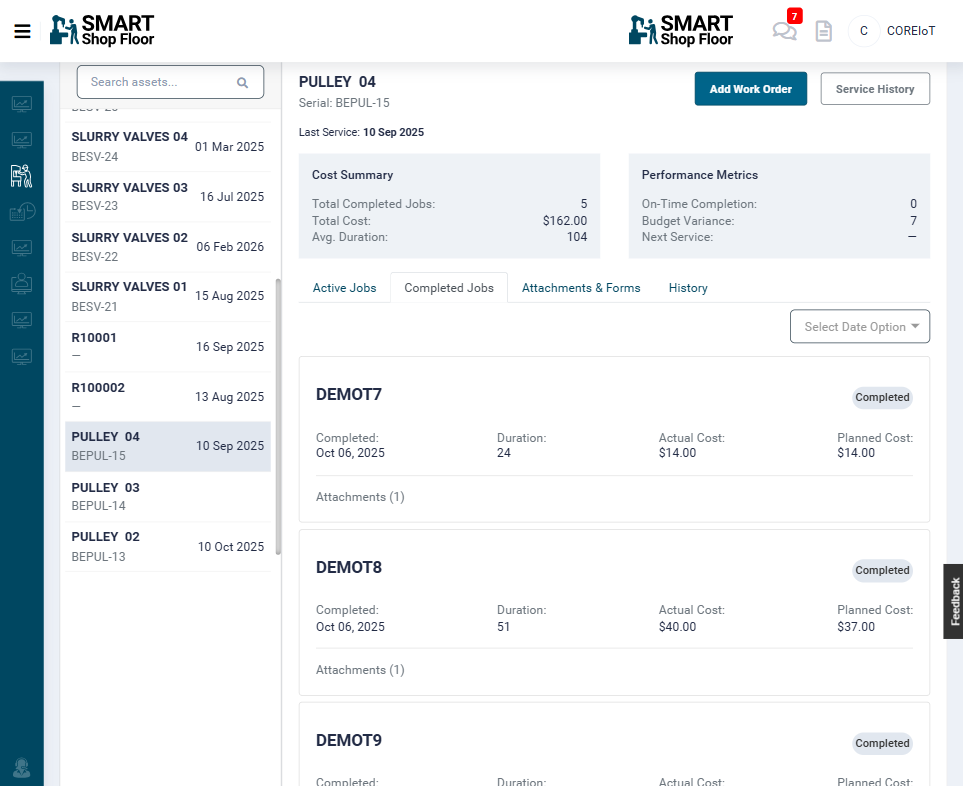

Inspection Reports

This entire process starts with a strip and assess. To speed up the inspection and make it easier to complete a condition report on a tablet, Smart Shop Floor automatically fills in customisable equipment details from your operations system. Staff just fill in the pertinent details, record photos and file the digital form, which creates a detailed record saved to the part.

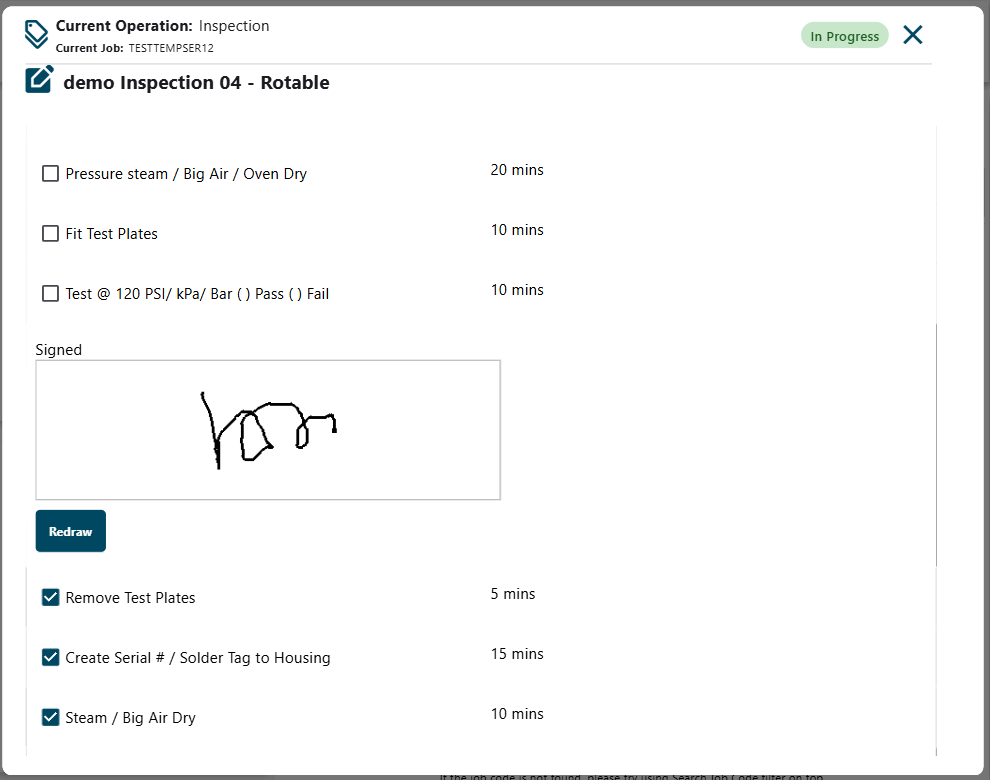

Customer Approval & Communication

Once the inspection is complete, the report is sent automatically to the customer for review. They approve or reject the Forward Maintenance Plan (the repair quote) through the Customer Portal—a secure web interface showing real-time data on quotes, work progress, and estimated completion dates. Customers authorise work before you commit resources, giving both parties documented approval and clear expectations. After approval, the work proceeds to scheduling.

Inventory and Scheduling

Every rotable has its own bill of materials and maintenance schedule. Our AI agent SAM flags parts due for retrofitting while also ensuring that the needed materials are in stock, predicting missing BOM items based on standard repair intervals. Once materials are confirmed available, the production planning and scheduling module coordinates the repair work, assigns labour and ensures the job stays on pace. You get granular control, scheduling and recording work for sub-components.

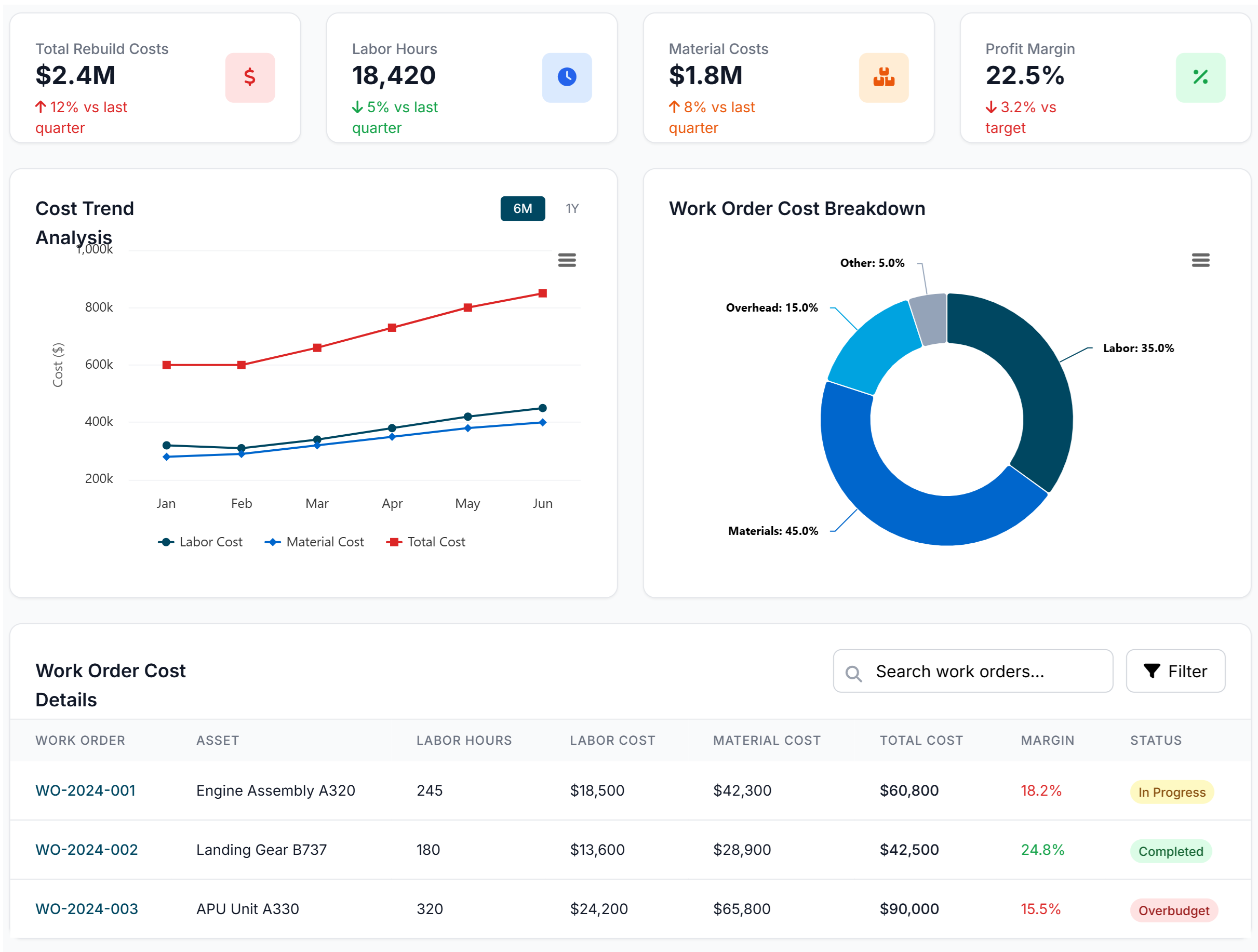

Cost Analysis

Managing lifetime rebuilding costs is difficult, with no single reference point and every cost a different line item. The Rotable Dashboard displays detailed costing including labour hours and materials cost for each work order. Smart Shop Floor reviews these numbers to spot any downward trends, where you might have thinning margins and need to adjust course. This way you catch cost creep early, before it eats into profit.

The shop floor scheduling solution that gets the job done.

We bring together everything you need to schedule and manage your shop floor. Save time, reduce downtime, and boost productivity.