Truss and Frame Component Manufacturing

Wood and steel structural component manufacturers face unique challenges in an industry where delivery dates shift frequently with construction’s variable nature. Smart Shop Floor keeps projects moving by automating customer communications around shifting delivery dates, drawing approvals, and site readiness - so you're not chasing down details that derail production schedules.

Made By Job Shops,

For Job Shops

When leading Australian job shops couldn’t find scheduling software that understood their complexity, they collaborated with us to build one from scratch. After four years of testing and development, Smart Shop Floor is the only production scheduling system made by job shops, for job shops.

Industry Challenges

Real Solutions to Your Real Problems

Solution

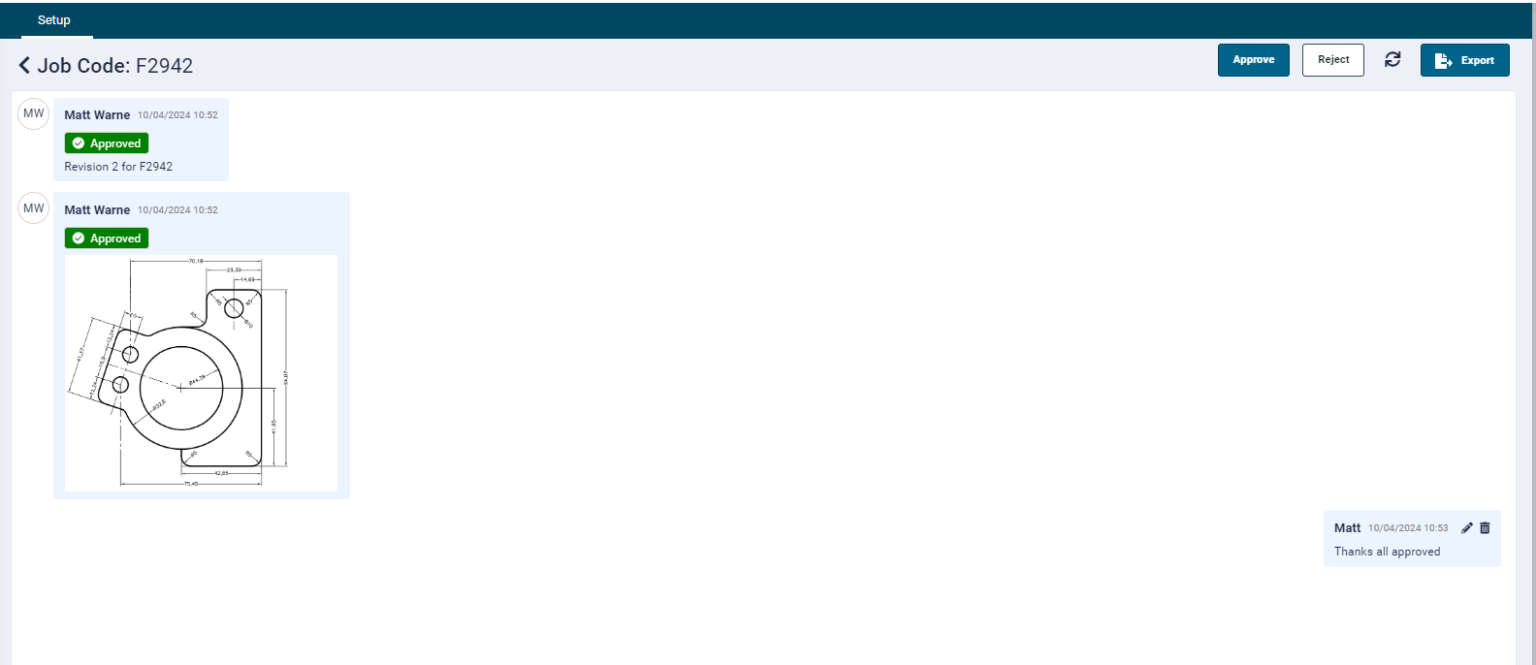

Get Firm Commitments in Writing

Get every delivery commitment in writing with Smart Shop Floor's Customer Portal. Establish timestamped client approvals for committed dates and create clear paper trails around timeline dependencies. This keeps everyone on the same page with unified communication—it's clear that manufacturing depends on receiving signoff, which prevents last-minute changes that leave you holding the bill.

Problem 1

Constantly Changing Required Dates

When delivery dates change after verbal agreements, you're left with completed components taking up valuable yard space and tied up working capital. Without clear documentation of who agreed to what and when, you're left absorbing costs with little recourse.

Solution

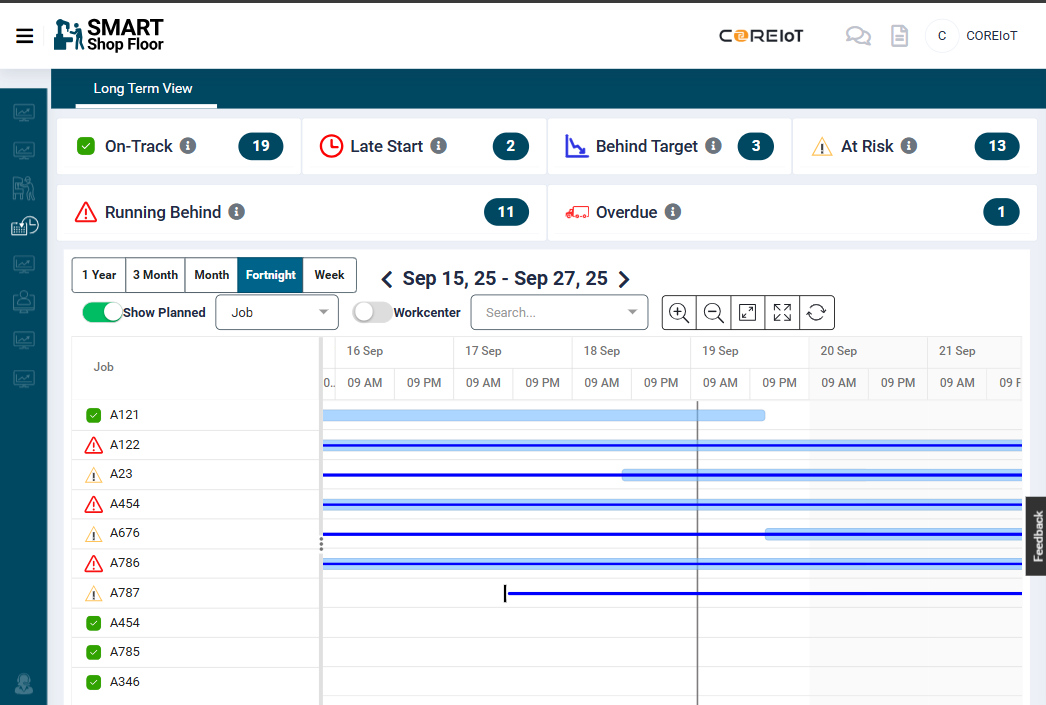

Build and Ship with Just-in-Time

Smart Shop Floor connects your schedule and production for the first time, enabling just-in-time manufacturing. You make orders as close to delivery dates as possible, which requires scheduling flexibility that responds to changes and constraints. With requirement dates locked in, you produce when needed and ship immediately, so nothing sits waiting in your yard.

Problem 2

The Yard Isn’t Big Enough

Extending due dates leads to another problem. You're left holding completed components in your yard until the site is ready for delivery, but this requires significant money and space. You risk running out of space or paying for extra square footage just to be a holding point.

Solution

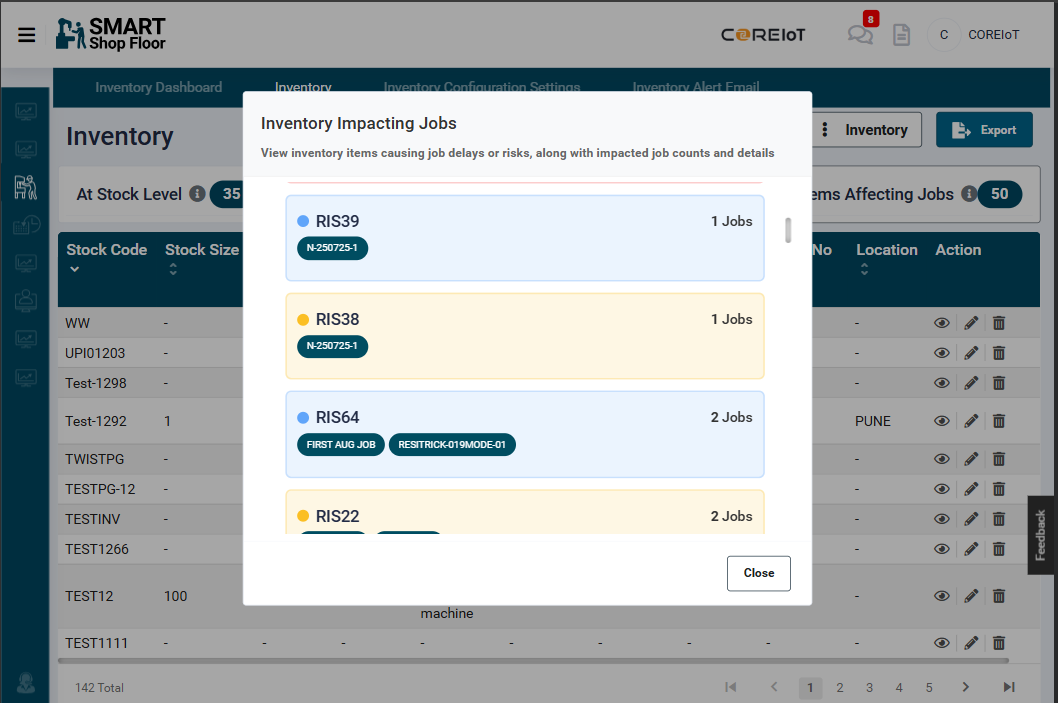

Rush Jobs Without the Premium

Smart Shop Floor's just-in-time scheduling means you don't need to hold safety stock to buffer against customers changing due dates, reducing your inventory. With exact lead times and materials planning, you have more predictable material consumption and can order when needed rather than stockpiling. Automated scheduling is so efficient that it accommodates rush orders without requiring overtime or new hires.

Problem 3

Profit Losses from Rush Orders

Rush orders put you in a constant squeeze. You never know if customers will move their dates up, so you hold excessive inventory, tying up cash and storage space. When a last-minute order comes in and you can't fulfil it from stock, you're stuck paying overtime or hiring temps, often at a loss.

The shop floor scheduling solution that gets the job done.

We bring together everything you need to schedule and manage your shop floor. Save time, reduce downtime, and boost productivity.